Mining Intelligence Software

Our enterprise products collect, analyse and report information across the value chain along with logistics and contract management, supply and demand planning and trading and risk management.

Enable Digital Transformation for the Delivery of your Capital Projects

Scenario is a central hub having all your project information, documents, communications and processes. Our digital platform enables you to bring together all the vital information for your portfolio of projects which is securely digitised, giving you ownership of information while ensuring data consistency and transparency for intelligent analysis and insights.

Capture data from the early phases of feasibility and all along the execution path to deliver comprehensive information to operations teams. Scenario is the Single Source of Truth for all project stakeholders throughout the project lifecycle, which connects teams and allows seamless collaboration between stakeholders across the globe.

Scenario is highly configurable to suit your project and business needs as you progress through different project phases, allowing you to scale as you grow. We recognise the importance of flexibility in supporting the complexity of mega-projects in an ever-evolving space of digital transformation.

Make better decisions with the aid of near real-time Dashboards & Reporting, and reduce your Project Risk. We understand the significance of breaking down data silos in delivering complex mega-projects. Dashboards and Reporting are configured with accurate and consistent project data to provide real-time insights and reveal the true position of the projects. Scenario keeps the project team alerted and informed to support accurate and timely decisions to mitigate potential risks.

Rework, and sharing of wrong revisions cost money! Capturing all project data and processes in Scenario throughout the project lifecycle, you can be confident that all stakeholders are working together on the latest revision and have access to the most accurate data. With this assurance, you can avoid unnecessary reworks and delays in the project.

Adopting Scenario improves the transparency in your Portfolio and leads to more effective handovers. Scenario provides a centralised platform to establish a standardised way of managing project information, collaboration and document control across their Enterprise Portfolio at all project stages.

Our clients have seen an average of 50% turnaround time in review processes.

Scenario facilitates borderless collaboration and sharing of information across internal and external parties with access from anywhere through our web-based and mobile applications. Our automated workflows and concurrent review tools further digitise processes for increased speed and efficiency.

A searchable audit trail of communications, information history and key decisions is established in Scenario from the start. With a comprehensive history of your project activities, you can easily and swiftly resolve disputes by identifying events and parties involved.

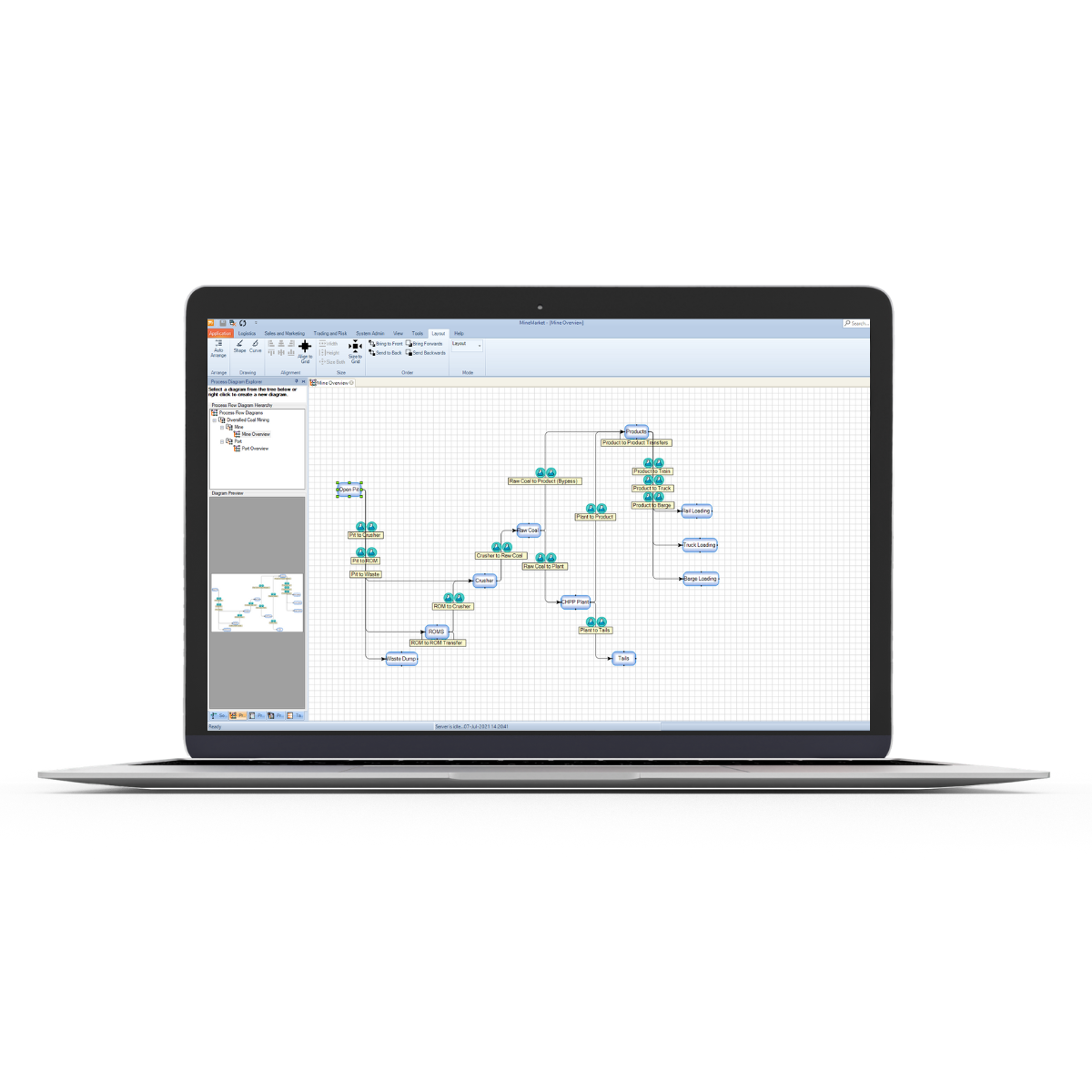

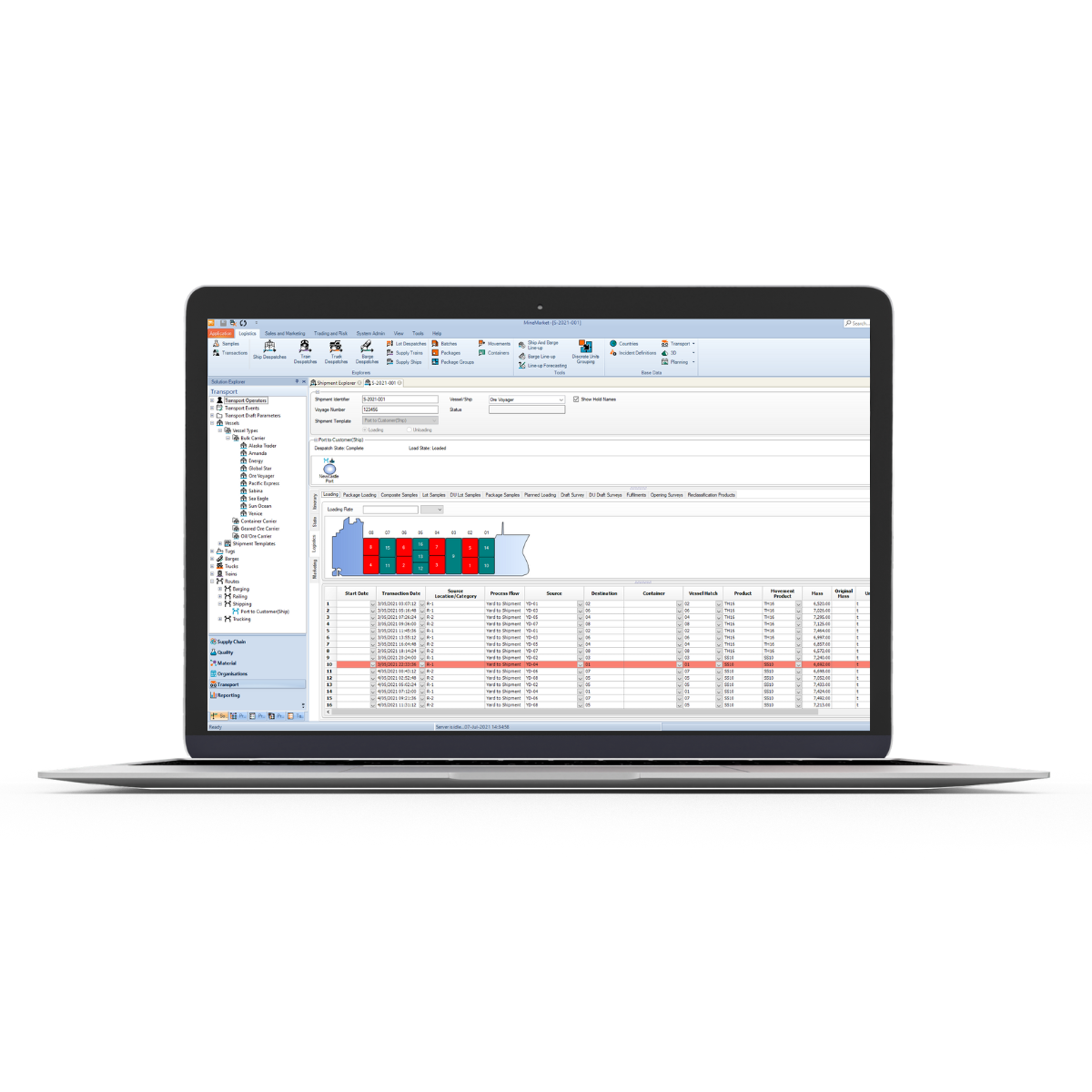

Minemarket Complete mine-to-market solution

The broadest coverage for managing the mining value chain

Complete mine-to-market solution

MineMarket provides the broadest coverage for managing the mining value chain by combining comprehensive material tracking, logistics management, and complex sales and marketing capability into a single solution. Through connecting operational data and its relationships from mine-to-customer, MineMarket maximises commercial outcomes by optimising logistics, charting the impact of sales, and tracking and identifying operational bottlenecks. It minimises delays in data collection, ensuring the same data is visible across the organisation, which facilitates analysis, adjustment and reconciliation. MineMarket can be used in conjunction with other business systems, integrates seamlessly with other Datamine solutions, and provides sophisticated reporting and web service integration capabilities.

MineMarket replaces the need for disparate technical and commercial systems, and provides stakeholders with real time access to key performance indicators such as production, inventory, quality, delays and contract information.

MineMarket enforces the standardisation of business processes by providing common data collection mechanisms throughout the entire supply chain. These can be performed automatically or via predefined data entry forms, and improve consistency in meeting contractual requirements.

The blending and planning functionality provides both the ability to consistently blend as well as visibility of stock shortages and quality problems well into the future. These tools give users the ability to efficiently plan sales, to react to changing market situations with flexibility and speed, and to consistently deliver top contract specifications.

MineMarket supports and automates marketing desk processes, providing sophisticated tools to allow companies to compete efficiently in a global market. Integrated with production, finance and accounting systems, the solution supports product flow forecasts, trading commitments, shipment planning, invoicing, assay exchange, credit management, cash flows and many other sales and marketing functions.

MineMarket ensures that all generated data is traceable to and complies with the corresponding contractual arrangements, as well as maintaining complete audit details of every transaction.

Centric

Mining Intelligence Software

A single revealing stream of information that provides timely insights and irrefutable facts you can rely on

Your entire enterprise into one integrated ecosystem

Centric pulls together your entire enterprise into one integrated ecosystem that gives you a clear view of your mine’s performance. We eliminate inefficient processes related to data acquisition, reporting, and analysis that keep mines from realizing their full potential.

Sleek, simple mobile and desktop applications – combined with sophisticated integration tools collect the most useful data from across business silos (fleet, processing, finance, etc.) and uncover relationships and correlations that directly affect your bottom line. This single revealing stream of information provides the timely insights and irrefutable facts you can rely on to make informed decisions and drive your business forward with confidence.

Incorporate all mine metrics with integration to existing mining data systems and user/supervisor data entry forms, into a single source of truth including employee activity, development, consumables, budgets, forecasts, targets and other mining related metrics.

Incorporate all fleet and equipment related metrics into your single source of truth. Mobile or fixed asset utilization data can be sourced from existing systems (fleet management, process control systems, etc.), entered by operators using Centric’s operator entry forms, or a combination of both.

Incorporate all processing metrics such as fixed asset operating data, slurry or fluid flows, power consumption, consumable usage, and operators time and activities into Centric. This data can be sourced from existing onboard systems (Scada Systems) or entered by operators using Centric’s operator entry forms, or a combination of both.

Incorporate all material haulage metrics into a single source of truth including but not limited to material movements. Haulage information may include basic quality data (material types, grade assignments) as well as material conveyance metrics (fleet movements, conveyor belt readings, weightometer readings) to provide basic mine haulage and production reporting.

Use Centric’s Drill & Blast module to enter, track and report consumables, delays, drill hole metrics, blast metrics, photos and more. Incorporate costing and production data in advanced analytics for a broader understanding of drill & blasts impact on the business.

Use Centric’s Health and Safety module to enter and track incidents, risks and hazard remediation, training requirements, and action plans. Include production data for a broader understanding of Health and Safety and use it to predict health and safety performance.

Incorporate all environmental metrics into your single source of truth. Integrate directly to commercial lab systems for efficient integration of sample results. Use advanced analytics and QAQC tools to monitor sampling programs.

Regardless if the sampling is in support of grade control, plant operations, environment monitoring or reconciliation, Centric Sample Management ensures that there is a single source of truth based on central business rules, QAQC processes, and validation.

Ore Accounting uses metrics and workflows related to ore movements to provide accurate and auditable accounting of your material. Centric’s reconciliation empowers users to measure the performance of key pillars of the business by accounting for gains and losses of production.

Access Centric’s metallurgical balancing tool to gain valuable information about plant operations, recovery rates, plant mass balance and potential areas of material losses.

Reconcilor.

Metal Reconciliation

Track metal movement from start to finish with confidence

Mining intelligence system

Reconcilor is a HTML5 web application and makes use of modern web technologies to deliver improvements to the reconciliation process, with subsequent results-driving value across the entire mining chain, from resource to mine to plant product and shipping. It is the culmination of years of experience and evolution, working on global mining reconciliation and optimisation projects. Reconcilor will give you confidence in your Resource, Ore Reserve and Grade Control Model estimates which will improve the accuracy of stock level tonnes, grade and metal availability for blending and supply chain opportunities.

Regular data imports and validation allow early detection of data issues well before the end-of-month, allowing you to make informed decisions and leaving more time for implementing improvements. Take the hard work out of your reconciliation and start reaping the benefits.

Through simple yet powerful integration, Reconcilor provides a complete picture of your operation by combining data from the following sources: Geological models, Survey, Mine plans, Dispatch, Plant movements and sampling and Transport and shipping (optional).

The entire Reconcilor web interface is “deep linked” so content can easily be shared amongst users without the need to export data. Miscommunication is rife at most mine sites, often leading to costly mistakes. Reconcilor safeguards against naming inconsistencies and deviation from a given mine plan.

If not managed carefully stockpiles can pose a significant challenge to your reconciliation. Reconcilor automatically calculates stockpiles balances using a choice of several modelling types, giving you instant access to the information you need.

Develop a deep understanding of your operation through this powerful analysis tool, allowing almost any mining or planning metric to be compared and relationships identified. Optimise future production by examining past trends and put in place measures to stop history repeating itself.