Customer Success Story: Bellevue Gold & Reconcilor

The successful integration of Reconcilor and LiveMine has provided significant benefits to Bellevue

The customer

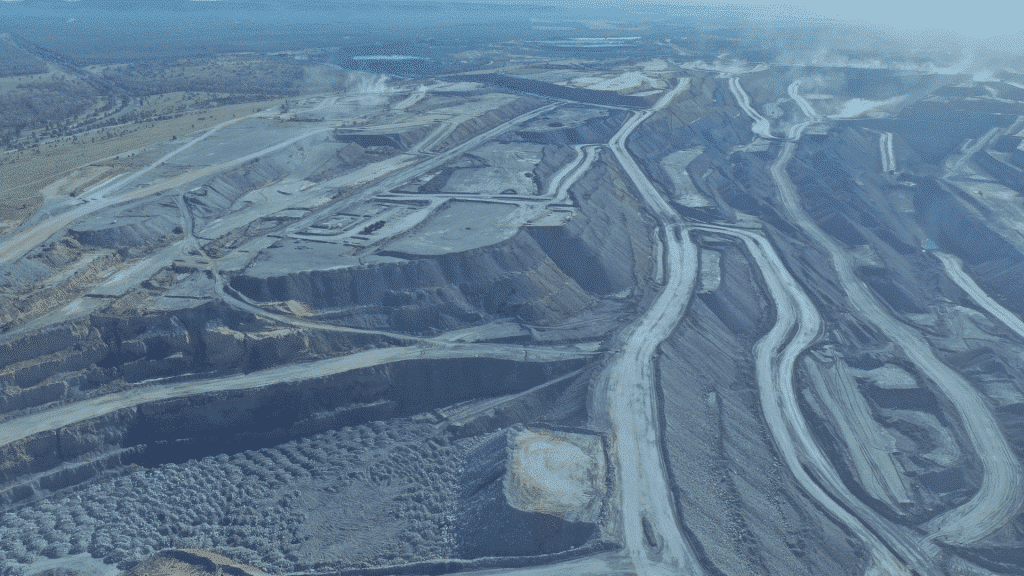

Bellevue Gold Limited is a publicly traded company on the Australian Securities Exchange (ASX). Ithas a current independent JORC Compliant global Mineral Resource of 9.8 Mt at 9.9 g/t gold for 3.1Moz, which includes a Probable Ore Reserve of 6.8 Mt at 6.1 g/t gold for 1.34 Moz. The historic Bellevue Gold Mine in Western Australia holds one of the highest-grade gold discoveries in the world.

The Bellevue Gold Project is situated in the Goldfields region of Western Australia, about 40km northwest of Leinster, in a major gold and nickel-producing district. The company is developing a high-grade underground gold mine at the Bellevue Gold Project. The mine plan includes a 1.0 Mt per annum processing plant, which will use a conventional gravity and leaching circuit. Mining operations will focus on underground production from multiple production centers accessible from the same portal.

The challenges

Meeting the anticipated high grade and cost-effectiveness of the Bellevue Gold Mine during its first five years of operation is crucial. To achieve this, it is necessary to establish and improve the means of tracking and evaluating the effectiveness of the mining process about the model estimates before the start of production.

The solution

Services selected to solve the above challenges

- Mining Contractor: Develop

- Dispatch software: LiveMine

- Reconciliation software: Reconcilor

Here are some potential benefits:

- Improved data management: Reconcilor enables routine data imports and validation, enabling timely detection of any data issues. This proactive approach to data management can help ensure the accuracy and reliability of the data, leading to informed decision-making and improved performance.

- Streamlined reconciliation process: By utilising Reconcilor, the reconciliation process can be streamlined, saving time and effort. This can lead to increased productivity and efficiency.

- Real-time data collection: LiveMine enables real-time data collection, providing instant feedback on the mining process. This can help identify any issues as they occur, allowing for timely intervention and corrective action.

- Improved data quality and reliability:LiveMine’s streamlined design, specifically tailored to meet the needs of mining operators, facilitates seamless data collection and reporting. This can help ensure the accuracy and reliability of the data, leading to informed decision-making and improved performance.

- Enhanced operational productivity:The efficiencies gained from using LiveMine have been proven to enhance operational productivity while minimising errors and ensuring data accuracy. This can lead to increased profitability and cost-effectiveness.

The results

The successful integration of Reconcilor and LiveMine has provided significant benefits to Bellevue, including standardisation of location hierarchy across all data sources, confidence in the quality of data before analysis and reporting, and tracking of spatial and mining compliance across multiple mine plans. This has enabled the implementation of an optimised stockpile management system, leading to improved blend quality and optimal material allocation for plant processing.

LiveMine has demonstrated its ability to track all Hauling, Loading, Development Drilling comprehensively, and Production Drilling operations at Bellevue, achieving high levels of automation and data accuracy. In addition, the upcoming launch of its Explosives Management product will provide an end-to-end system for tracking and managing explosives across the minesite, delivering significant value across the entire drilling to the charging process.

Develop is also planning to trial LiveMine Shift Planning, which will enhance the operation’s ability to plan and execute their shifts with maximum efficiency while enabling direct task assignment to operator tablets. This will significantly reduce the risk of costly errors, resulting in an impressive 95% automated data entry of the haulage data.

LiveMine has demonstrated its ability to replace paper PLODs for most major onsite operations and has successfully digitised vital processes such as pre-starts, shift planning, TKM tracking, and equipment time usage recording. These efficiencies have been proven to enhance operational productivity while minimising errors and ensuring data accuracy.

Company

- Bellevue Gold Limited

Industry

- Gold

Region

- Western Australia

Software Solution

- Reconcilor

Challenges

- Mining Contractor, not owner operator (outsourced work)

- Multiple source systems on site

- New software implemented, new users

- No ease in comparing the models with mining

- Difficulty measuring mine compliance

- No established process to measure the performance of the Resource model and data

- Inputs along the mining value chain due to the infancy of the project

Outcomes

- Tracking of spatial and mining compliance across multiple mine plans

- Optimised stockpile management system

- Improved blend quality

- Optimal material allocation for plant processing

- Standardisation of location hierarchy across all data sources

- Confidence in the quality of data before analysis and reporting

Social Media

See our blogs

Minemax Scheduler 7.7

October 14, 2024

Critical Analysis of Nature Positive Law Reforms

June 27, 2024

-

Peabody & Datamine Consulting

Peabody Identified Gaps Within Their Operations And Improved Their Overall Technical Capacity With Datamine's Consultants

-

Rio Tinto & CCLAS

Automated Processes And Tracked Data Flows Enabled Rio Tinto To Improve Operational Outcomes - Saving Up To 1 Month Per Year In Manual Work, Significantly Minimising Data Errors And Increasing Processing Capacity

-

Advaita Group DMCC & MineMarket CTRM

Better Informed Decision Making And Data Analysis, And Significant Time Savings On EOM Reporting Using MineMarket