Customer Success Story:

Rio Tinto & CCLAS

Automated Processes and Tracked Data Flows Enabled Rio Tinto to Improve Operational Outcomes - Saving Up to 1 Month Per Year in Manual Work, Significantly Minimising Data Errors and Increasing Processing Capacity

The customer

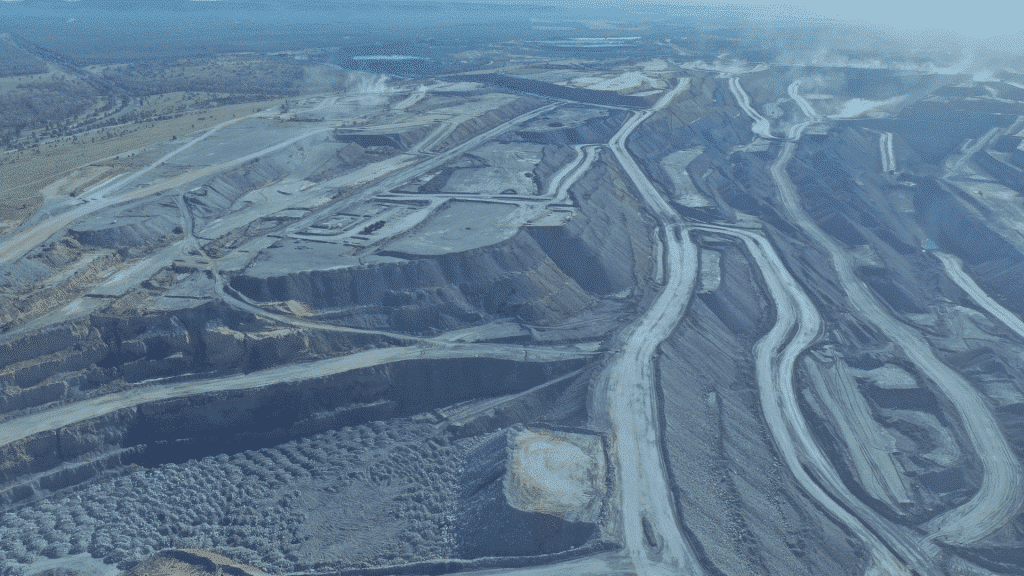

Rio Tinto is the world’s second-largest metals and mining corporation, producing materials essential to human progress. This includes iron ore, aluminum, copper, borates, titanium and diamonds. Rio Tinto operates in 35 countries around the globe in mines, smelters and refineries, as well as in sales offices, data centers, research and development labs and with artificial intelligence. Rio Tinto have almost 50,000 employees globally, with a strict vendor selection process and high standards to meet. They focus on partnering and engaging local suppliers, products and services and are an industry leader in best practice and innovation.

The challenges

Similar to many mining laboratories, Rio Tinto was seeking a single solution to manage their laboratory processes seamlessly. Without a system for laboratory information management, mining operations often experience costly inefficiencies and data entry errors – issues that are almost unavoidable with manual processes, but which can have a significant negative impact on operational outcomes.

“Instead of manually calculating weighted averages for our export samples, and daily composite averages; these are now automatically completed using a script to reduce error and increase efficiency,” said Aaron Hanshaw, Laboratory Specialist, at Rio Tinto Weipa.

The team also raised specific challenges they experienced previously such as a lack of operational efficiency, data entry errors, the need for manual data upload, and a number of samples that did not meet conformance standards. This also meant that highly qualified team members spent unnecessary time on repetitive, manual tasks rather than high-level work that required their expertise.

For Rio Tinto, this called for a system to rectify these challenges and optimise their laboratory information management with a more efficient, accurate and reliable data management system.

“Instead of manually calculating weighted averages for our export samples, and daily composite averages; these are now automatically completed using a script to reduce error and increase efficiency,” said Aaron Hanshaw, Laboratory Specialist, at Rio Tinto Weipa.

The team also raised specific challenges they experienced previously such as a lack of operational efficiency, data entry errors, the need for manual data upload, and a number of samples that did not meet conformance standards. This also meant that highly qualified team members spent unnecessary time on repetitive, manual tasks rather than high-level work that required their expertise.

For Rio Tinto, this called for a system to rectify these challenges and optimise their laboratory information management with a more efficient, accurate and reliable data management system.

The solution

Over 20 years ago, Rio Tinto Weipa turned to Datamine seeking a solution for these challenges. CCLAS EL automates laboratory processes through flexible sample registration, barcode label printing, work list generation, online data capture from a wide range of analytical instruments, and automatic generation of analytical reports and commercial invoices. The system offers superior quality control functions that monitor operation product materials and quality control reference standards against specifications. CCLAS enables high-volume, complex analytical laboratory data to be captured, calculated, and stored with utmost confidence and reported to the client efficiently and on time. It is in use by major mining companies and commercial testing laboratories worldwide, across a wide range of operations, from simple stand-alone systems through to complex multi-site systems.

CCLAS minimises labour costs and improves data accuracy through increased laboratory automation, reduced efforts in manual data entry, and eliminates standalone data storage such as spreadsheets. It also assists with the laboratory’s certification processes by recording changes of results and enables effective business intelligence and corporate data mining by providing a single, comprehensive, and standardised system. CCLAS also enables mining operations and commercial laboratories to meet increasing regulatory compliance and auditing requirements by ensuring quality control over the results generated through the built-in QC and auditing process.

CCLAS minimises labour costs and improves data accuracy through increased laboratory automation, reduced efforts in manual data entry, and eliminates standalone data storage such as spreadsheets. It also assists with the laboratory’s certification processes by recording changes of results and enables effective business intelligence and corporate data mining by providing a single, comprehensive, and standardised system. CCLAS also enables mining operations and commercial laboratories to meet increasing regulatory compliance and auditing requirements by ensuring quality control over the results generated through the built-in QC and auditing process.

The results

As a CCLAS user of more than 20 years, the benefits for Rio Tinto Weipa’s after implementing the solution is incalculable. Integrating CCLAS into their laboratories has enabled Rio Tinto and the team to provide consistently accurate data with minimal errors, and low numbers of non-conformance samples.

CCLAS has significantly reduced the manual data input which ultimately reduces any operator error. Something as simple as an automated step can influence a magnitude of factors. Aaron Hanshaw explains that “From a personal operator experience, this can enable a reduction in external time pressures at the start of shift, utilising Human Performance tools such as “slow is smooth, smooth is fast”. Further, in an ever rapidly growing and changing industry, remaining vigilant in continuous improvement is key and through streamlining and automating steps, we can remain competitive.”

Aaron Hanshaw shares that, “A task that required at least an hour of time every morning is now automatically completed by the script.” Simple automations such as this which are now actionable with script rather than manually save the team a minimum of 30 hours a month, time which quickly adds up and can be redirected towards more meaningful work. Rio Tinto Weipa’s labs operate 24 hours every day – saving the laboratory a whole month per year in time.

CCLAS also enabled Rio Tinto to integrate a wide range of laboratory instruments used in analysis to automatically upload data into the Data Entry fields – once again upgrading a manual process into a simple automation.

Without a doubt, CCLAS has also enabled Rio Tinto Weipa to target quality tonnes. Quality bauxite has a significant impact in the market and with the utilisation of CCLAS in automating steps and online data entry, the Lab can provide faster turnaround times on accurate sample analysis providing their stakeholders with key results to input into RAPID decision making.

Streamlining the registration and data entry of samples mean the laboratory is able to process even more samples on a daily basis and enables faster throughput – figures which quickly add up to deliver valuable time back for their operations.

After seeing the significant impact of CCLAS at Rio Tinto Weipa’s site, they also implemented the solution at two other laboratories – Amrun and Gove, a testament to the felt impact of this solution within Rio’s operations.

CCLAS has significantly reduced the manual data input which ultimately reduces any operator error. Something as simple as an automated step can influence a magnitude of factors. Aaron Hanshaw explains that “From a personal operator experience, this can enable a reduction in external time pressures at the start of shift, utilising Human Performance tools such as “slow is smooth, smooth is fast”. Further, in an ever rapidly growing and changing industry, remaining vigilant in continuous improvement is key and through streamlining and automating steps, we can remain competitive.”

Aaron Hanshaw shares that, “A task that required at least an hour of time every morning is now automatically completed by the script.” Simple automations such as this which are now actionable with script rather than manually save the team a minimum of 30 hours a month, time which quickly adds up and can be redirected towards more meaningful work. Rio Tinto Weipa’s labs operate 24 hours every day – saving the laboratory a whole month per year in time.

CCLAS also enabled Rio Tinto to integrate a wide range of laboratory instruments used in analysis to automatically upload data into the Data Entry fields – once again upgrading a manual process into a simple automation.

Without a doubt, CCLAS has also enabled Rio Tinto Weipa to target quality tonnes. Quality bauxite has a significant impact in the market and with the utilisation of CCLAS in automating steps and online data entry, the Lab can provide faster turnaround times on accurate sample analysis providing their stakeholders with key results to input into RAPID decision making.

Streamlining the registration and data entry of samples mean the laboratory is able to process even more samples on a daily basis and enables faster throughput – figures which quickly add up to deliver valuable time back for their operations.

After seeing the significant impact of CCLAS at Rio Tinto Weipa’s site, they also implemented the solution at two other laboratories – Amrun and Gove, a testament to the felt impact of this solution within Rio’s operations.

Company

- Rio Tinto

Industry

- Mining

Region

- APAC

Software Solution

- CCLAS

Challenges

- Costly operational inefficiencies

- Tedious, manual data entry

- Lack of transparency into data flow

- Expert team members working on admin tasks

Outcomes

- Automated data processing

- Significant improvement in data accuracy

- Timely data insights

- Faster turnaround on sample analysis

Social Media

See our blogs

Studio OP V3.0 Release

June 10, 2024

New product alert! – CCLAS EL Mobile App v1.0.0

April 29, 2024

DATAMINE EXPANDS ASSET MANAGEMENT SOLUTIONS

April 15, 2024

-

Peabody & Datamine Consulting

Peabody Identified Gaps Within Their Operations And Improved Their Overall Technical Capacity With Datamine's Consultants

-

Rio Tinto & CCLAS

Automated Processes And Tracked Data Flows Enabled Rio Tinto To Improve Operational Outcomes - Saving Up To 1 Month Per Year In Manual Work, Significantly Minimising Data Errors And Increasing Processing Capacity

-

Advaita Group DMCC & MineMarket CTRM

Better Informed Decision Making And Data Analysis, And Significant Time Savings On EOM Reporting Using MineMarket