Customer Success Story:

Evolution Mining & Reconcilor

Utilising best practice with Reconcilor enabled Evolution Mining to improve operational outcomes - meaning reduced processing time, improved data validation and accuracy, significantly improved stockpile balancing and easy comparison between variables.

The customer

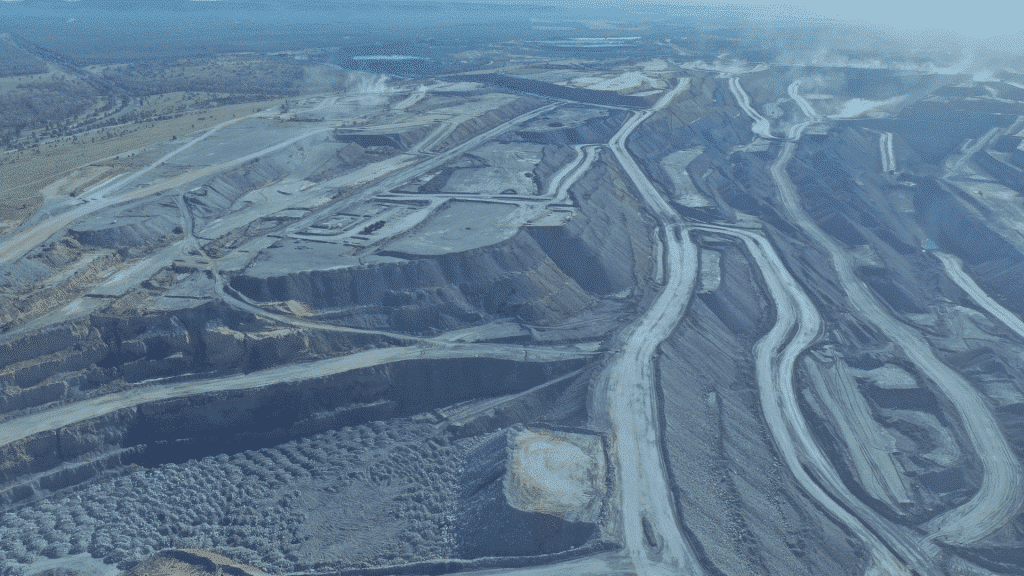

Evolution Mining is a global gold mining business with operations in Australia and Canada. Within its Australian assets is the Cowal Gold Operation (Cowal), located 350km west of Sydney, New South Wales. Cowal is a world class, open pit and underground gold operation with a long mine life and a low cost asset that will be the cornerstone of the Evolution story for many years to come.

The challenges

Like many operations, Cowal’s team was conscious of the time being consumed in maintaining daily, weekly and monthly excel spreadsheets via manual data entry from multiple data sources. Using multiple data sources, monthly reconciliation reporting was onerous, and a process they identified which could be resolved with the right tools and systems.

Having exposure to the success of Reconcilor at other sites, the Cowal team called for a change, seeking digital transformation to deliver a more efficient and accurate system for their data collection, assessment and reconciliation.

Having exposure to the success of Reconcilor at other sites, the Cowal team called for a change, seeking digital transformation to deliver a more efficient and accurate system for their data collection, assessment and reconciliation.

The solution

Cowal made the decision in 2019 to implement Reconcilor and together with the team at Snowden have streamlined their data capture, data quality control, analysis and reporting from the Resource model to the Cowal processing plant. They now have visibility of all surface material movements, up to date stockpile balances, model depletions and the ability to compare and see trends in any of the data points along the mine value chain from a temporal, spatial or physical point of view. All of that without any manual data entry, the removal of excess spreadsheets and confidence that the data they are using has passed through a rigorous data health engine.

Reconcilor offers an operation the transparency it needs to track metal movement from start to finish and to mine with confidence. Metal loss linked to poor mine reconciliation is an industry wide problem in the resources sector. This process is meant to identify differences between estimates, plans and actual mine production. Only once they are properly quantified and understood can steps can be taken improve metal balance. Unfortunately, some mine sites lack the skills, manpower or even confidence to undertake this analysis. Reconcilor empowers its users to take the next step by automatically consolidating and validating the data as well as offering spreadsheet free analysis. Regular data imports allow early detection of data issues well before end of month. This allows users to make informed decisions and leaves more time for implementing improvements.

Alex Moffitt, Senior Mine Geologist at Cowal shared their deal maker; “Reconcilor is the only reporting and reconciliation database system built with Mine Geology at its core – incorporating haulage, model, and processing information.”

He shares that the ‘Implementation and support team are very knowledgeable and engaging. Implementation through on-site data source mapping and form building allowed a solid working relationship to develop between site and Reconcilor implementation/support teams, aiding the development of future modifications and enhancements. Good balance of Operational Mine Geology and Software/Database/Technical in implementation and support team made it (seem) easy to come up with solutions to site-specific problems/intricacies.’

The Reconcilor implementation was performed within 8 weeks with Reconcilor being used in a production environment after a successful test phase.

Reconcilor offers an operation the transparency it needs to track metal movement from start to finish and to mine with confidence. Metal loss linked to poor mine reconciliation is an industry wide problem in the resources sector. This process is meant to identify differences between estimates, plans and actual mine production. Only once they are properly quantified and understood can steps can be taken improve metal balance. Unfortunately, some mine sites lack the skills, manpower or even confidence to undertake this analysis. Reconcilor empowers its users to take the next step by automatically consolidating and validating the data as well as offering spreadsheet free analysis. Regular data imports allow early detection of data issues well before end of month. This allows users to make informed decisions and leaves more time for implementing improvements.

The Plan

After identifying the need for a digital solution to their manual processes and recognising Snowden’s Reconcilor as a well-established solution for this – Cowal reviewed their options and engaged with the Snowden team to implement Reconcilor across the operation.Alex Moffitt, Senior Mine Geologist at Cowal shared their deal maker; “Reconcilor is the only reporting and reconciliation database system built with Mine Geology at its core – incorporating haulage, model, and processing information.”

He shares that the ‘Implementation and support team are very knowledgeable and engaging. Implementation through on-site data source mapping and form building allowed a solid working relationship to develop between site and Reconcilor implementation/support teams, aiding the development of future modifications and enhancements. Good balance of Operational Mine Geology and Software/Database/Technical in implementation and support team made it (seem) easy to come up with solutions to site-specific problems/intricacies.’

The Reconcilor implementation was performed within 8 weeks with Reconcilor being used in a production environment after a successful test phase.

The Trigger

A long mine life, stockpile management, and reporting through excel and manual data entry quality were all triggers to look for a more sustainable solution. Management and Geologists at Cowal had prior experience with Reconcilor, knowing the value it held for other operations. Their experience and insights into the benefits of the tool was a key driver in the pathway Cowal took in digital transformation using Reconcilor.The results

The impact of utilising a solution such as Reconcilor with scope across the entire mine value chain is significant – and one that is often difficult to define, and put a cost on benefit, in its entirety. Alex Moffitt, shares that their team has “reduced their daily processing time for reporting from over an hour, to less than 30 minutes per day”, regaining time that builds up quickly over an extended period. The team now has “more time spent validating data, improving data accuracy in production reporting (Mine and Mill Feed)”.

Improvements such as these mean that Cowal is now able to access “real time, live reporting and easily query information over any time periods (i.e., yearly, monthly, weekly, shift)”. The management of stockpiles is easier, with additions, depletions and balances readily available for any stockpile or stockpile group.

An outcome particularly impressive, noted by Alex was how Reconcilor provides easily “compares Mine Call vs Mill Call at the crusher and the comparison of the planned, surveyed and hauled tonnes to quantify over and undermining blocks”.

Since adopting Reconcilor, Evolution Mining has enhanced the ability to automate their reporting, which provides substantially more time for data validation and correction where necessary. They now have the ability to forward plan more effectively, looking at longer term trends and flexibility to generate reports and dashboards, while also noting the easy to use dashboards help to look at longer term trends in mining vs models vs processing.

Improvements such as these mean that Cowal is now able to access “real time, live reporting and easily query information over any time periods (i.e., yearly, monthly, weekly, shift)”. The management of stockpiles is easier, with additions, depletions and balances readily available for any stockpile or stockpile group.

An outcome particularly impressive, noted by Alex was how Reconcilor provides easily “compares Mine Call vs Mill Call at the crusher and the comparison of the planned, surveyed and hauled tonnes to quantify over and undermining blocks”.

Since adopting Reconcilor, Evolution Mining has enhanced the ability to automate their reporting, which provides substantially more time for data validation and correction where necessary. They now have the ability to forward plan more effectively, looking at longer term trends and flexibility to generate reports and dashboards, while also noting the easy to use dashboards help to look at longer term trends in mining vs models vs processing.

Company

- Evolution Mining

Industry

- Mining

Region

- APAC

Software Solution

- Snowden Optiro's Reconcilor

Challenges

- Time being consumed in maintaining daily, weekly and monthly excel spreadsheets via manual data entry from multiple data sources

- Using multiple data sources, monthly reconciliation reporting was onerous

- The need for a more efficient and accurate system for their data collection, assessment and reconciliation

Outcomes

- Reduced daily processing time for reporting from over an hour, to less than 30 minutes per day

- More time spent validating data & improving data accuracy in production reporting (Mine and Mill Feed)

- Now able to access real time, live reporting and easily query information over any time periods

- Reporting is automated, which provides substantially more time for data validation, correction where necessary, and to forward plan more effectively

- Easy to use dashboards help to look at longer term trends in mining vs models vs processing

Social Media

See our blogs

Studio OP V3.0 Release

June 10, 2024

New product alert! – CCLAS EL Mobile App v1.0.0

April 29, 2024

DATAMINE EXPANDS ASSET MANAGEMENT SOLUTIONS

April 15, 2024

-

Peabody & Datamine Consulting

Peabody Identified Gaps Within Their Operations And Improved Their Overall Technical Capacity With Datamine's Consultants

-

Rio Tinto & CCLAS

Automated Processes And Tracked Data Flows Enabled Rio Tinto To Improve Operational Outcomes - Saving Up To 1 Month Per Year In Manual Work, Significantly Minimising Data Errors And Increasing Processing Capacity

-

Advaita Group DMCC & MineMarket CTRM

Better Informed Decision Making And Data Analysis, And Significant Time Savings On EOM Reporting Using MineMarket