Customer Success Story:

Australian Iron Ore Company & MineMarket

Better Informed Decision Making and Data Analysis, as well as Significant Time Savings on EOM Reporting Using MineMarket for the Mining Sector

The customer

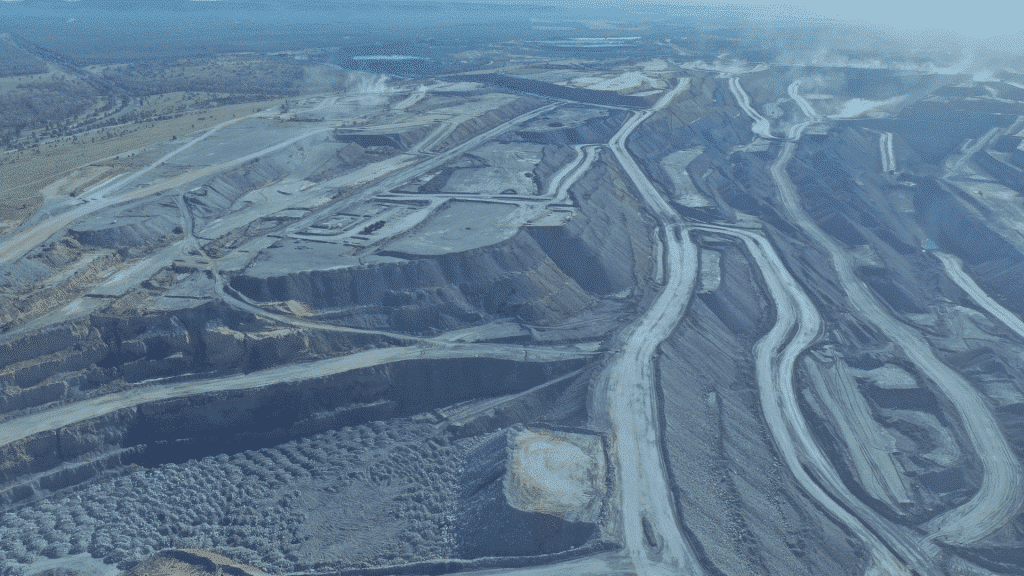

Our customer is an Australian owned iron ore company, whom exports and directly ships ore from its operations in the Pilbara, Western Australia. Due to the nature of the industry, this customer has requested to be de-identified.

The challenges

This mining company was experiencing challenges with managing data accuracy for their inventory, information flow and reporting which was not only time-consuming with manual checks, but made it difficult to access timely and verified reports.

Due to this disruption to data flow and lack of transparency, their team was spending unnecessary time on projects completing administrative work and double-checking data. Data integrity was a significant issue with the variety in data standards across operational functions, which meant it was often near impossible to pull accurate, up to date data to access immediate insights into site operations. Reporting was taking substantially longer than necessary due to multiple systems, different data formats, the need for multiple edits and data review processes.

The next layer in their challenge was data validation – when there are existing issues with accuracy and reporting, completing thorough, frequent validation becomes slow and laborious once again. Catching any issues in their operations may have been detected later than what is ideal and have had a larger impact. This company was seeking a solution to centralise and manage their inventory management system resulting in the selection of MineMarket. The need for a solution that centralised their data while improving data quality, was essential.

Due to this disruption to data flow and lack of transparency, their team was spending unnecessary time on projects completing administrative work and double-checking data. Data integrity was a significant issue with the variety in data standards across operational functions, which meant it was often near impossible to pull accurate, up to date data to access immediate insights into site operations. Reporting was taking substantially longer than necessary due to multiple systems, different data formats, the need for multiple edits and data review processes.

The next layer in their challenge was data validation – when there are existing issues with accuracy and reporting, completing thorough, frequent validation becomes slow and laborious once again. Catching any issues in their operations may have been detected later than what is ideal and have had a larger impact. This company was seeking a solution to centralise and manage their inventory management system resulting in the selection of MineMarket. The need for a solution that centralised their data while improving data quality, was essential.

The solution

To ensure effective and streamlined inventory management, MineMarket was chosen as the solution. MineMarket provides the broadest coverage for managing the mining value chain by combining comprehensive material tracking, logistics management, and complex sales and marketing capability into a single solution. Through connecting operational data and its relationships from mine-to-customer.

MineMarket maximises commercial outcomes by optimising logistics, charting the impact of sales, and tracking and identifying operational bottlenecks. It minimises delays in data collection, ensuring the same data is visible across the organisation, which facilitates analysis, adjustment and reconciliation. MineMarket can be used in conjunction with other business systems, integrates seamlessly with other Datamine solutions, and provides sophisticated reporting and web service integration capabilities.

MineMarket maximises commercial outcomes by optimising logistics, charting the impact of sales, and tracking and identifying operational bottlenecks. It minimises delays in data collection, ensuring the same data is visible across the organisation, which facilitates analysis, adjustment and reconciliation. MineMarket can be used in conjunction with other business systems, integrates seamlessly with other Datamine solutions, and provides sophisticated reporting and web service integration capabilities.

The results

With MineMarket fully implemented into their operations and customised to suit their needs, this Australian company is now able to run an automated monthly report to determine which pits have contributed to ship builds – a previously a time-consuming manual exercise. The ability to easily reconcile data and see at what point in the value chain variances have occurred is now possible with MineMarket – an invaluable datapoint for the team. Their newfound confidence in the integrity of their data has further enabled them to streamline processes and reporting whilst integrating with BI tools. “For us the implementation with Datamine was quite simple. As we have progressed with the product over the years, we continue to utilise more of the program’s functionality,” says their General Manager in Planning and Services. “Every time we look to take another step towards utilising more of MineMarket’s functionality the Datamine team has been great to work with.” By using MineMarket, confidence in the integrity of the data captured allows the company to make more informed and accurate planning decisions.

Company

- Iron Ore Company

Industry

- Mining

Region

- Australia

Software Solution

- MineMarket

Challenges

- Data accuracy for their inventory, information flow and reporting

- Unnecessary time spent on projects completing administrative work and double-checking data

- Near impossible to pull accurate, up to date data

Outcomes

- Now able to run an automated monthly report to determine which pits have contributed to ship builds

- The ability to easily reconcile data and see at what point in the value chain variances have occurred

- Confidence in the integrity of the data captured allows the company to make more informed and accurate planning decisions

Social Media

See our blogs

Studio OP V3.0 Release

June 10, 2024

New product alert! – CCLAS EL Mobile App v1.0.0

April 29, 2024

DATAMINE EXPANDS ASSET MANAGEMENT SOLUTIONS

April 15, 2024

-

Peabody & Datamine Consulting

Peabody Identified Gaps Within Their Operations And Improved Their Overall Technical Capacity With Datamine's Consultants

-

Rio Tinto & CCLAS

Automated Processes And Tracked Data Flows Enabled Rio Tinto To Improve Operational Outcomes - Saving Up To 1 Month Per Year In Manual Work, Significantly Minimising Data Errors And Increasing Processing Capacity

-

Advaita Group DMCC & MineMarket CTRM

Better Informed Decision Making And Data Analysis, And Significant Time Savings On EOM Reporting Using MineMarket