Customer Success Story:

ROMONTA & MineScape

Achieving over 95% accuracy in a complex historical mining district with the MineScape mine planning model.

The customer

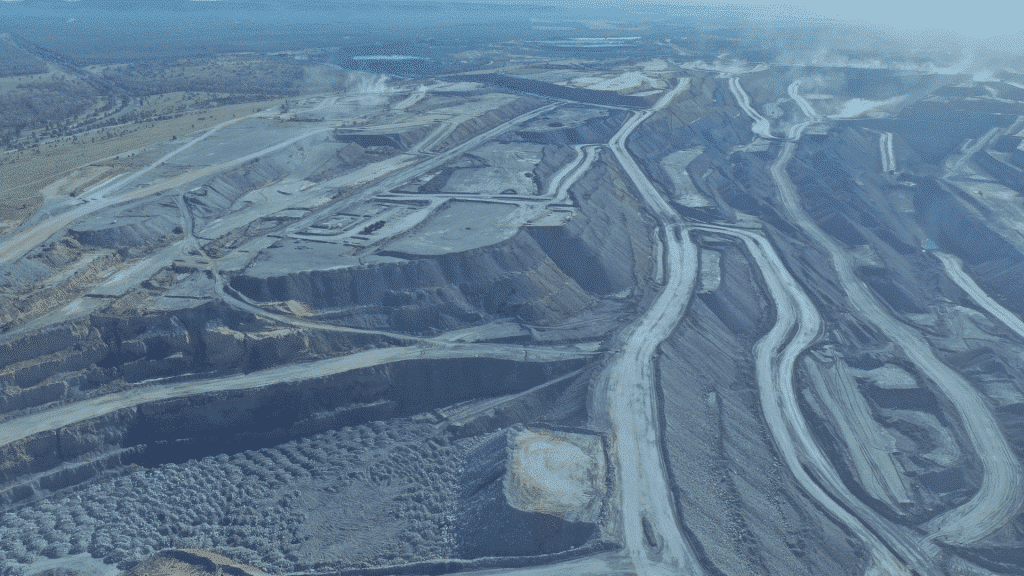

ROMONTA is the world’s largest crude montan wax producer. It operates the Amsdorf open pit mine, located in the Central German lignite mining area. From the bitumen-rich soft lignite, approximately 15,000 tonnes of crude montan wax are extracted per year from 500,000 tons of lignite. Over the past 100years, the deposit has been mined underground and open pit (on the outskirts of the mining area).

The challenges

When designing a mine site, an accurate geological model is an important foundation for the extraction planning. Knowledge about the mineral deposit, especially about the quantities and qualities, as well as the spatial location of seams, are important factors in optimised mine planning. In the lignite deposits of Amsdorf, new mining areas are rare, because historical open pit and underground mining operations have been in existence throughout the 19th and 20th centuries. Several independent mines were previously combined over time and consolidated to create today’s mine site.

As a result, confusing pit geometries across a network of underground mine tunnels and caving areas exist within the mine site. For these mining areas, little or no historical modelling has ever been done, although bitumen-rich lignite exists in quantities that are still economical to extract today.“ Geological modelling of old underground mines can be challenging because of their complex structures, especially the underground caves,” explains ROMONTA’s Maximilian Hertrampf. “Standard mine planning software provided insufficient modelling capabilities.”

As a result, confusing pit geometries across a network of underground mine tunnels and caving areas exist within the mine site. For these mining areas, little or no historical modelling has ever been done, although bitumen-rich lignite exists in quantities that are still economical to extract today.“ Geological modelling of old underground mines can be challenging because of their complex structures, especially the underground caves,” explains ROMONTA’s Maximilian Hertrampf. “Standard mine planning software provided insufficient modelling capabilities.”

The solution

To help address their unique challenges, ROMONTA turned to MineScape. Specifically developed to meet the mining industry’s rigorous demands, MineScape has been proven to outperform in the most complex mining operations throughout the world. MineScape is a suite of integrated solutions designed for use in open pit and underground mining operations for both coal and metalliferous deposits. It delivers extensive geological modelling and mine design functionality, making it the global leading mine planning solution.

The results

Using the MineScape solution, ROMONTA modelled the Amsdorf underground mine, including the complex infrastructure of old mines, to create an optimised mine plan model. The MineScape stratigraphic model incorporated a complex set of data consisting of:

• Old topography and mine maps.

• Complex old underground structures and caving systems.

• Current maps.

• Digital sources including drill hole data and quality analysis.

This data set was normalised into a single correct data source. A geological model was built that accurately represented the stratigraphic coal deposit with all the deformations caused by the old underground mining. A triangulated model of the old underground workings was constructed to visualise the areas affected by the past underground excavations. All this combined information provided an accurate geological and quality model, accurate resource estimates and mine plan.

• Old topography and mine maps.

• Complex old underground structures and caving systems.

• Current maps.

• Digital sources including drill hole data and quality analysis.

This data set was normalised into a single correct data source. A geological model was built that accurately represented the stratigraphic coal deposit with all the deformations caused by the old underground mining. A triangulated model of the old underground workings was constructed to visualise the areas affected by the past underground excavations. All this combined information provided an accurate geological and quality model, accurate resource estimates and mine plan.

Company

- ROMONTA

Industry

- Mining

Region

- EMEA

Software Solution

- MineScape

Challenges

- Geological modelling of old underground mines can be challenging because of their complex structures, especially the underground caves

- Confusing pit geometries across a network of underground mine tunnels and caving areas

- Standard mineplanning software provided insufficient modelling capabilities

Outcomes

- Data set was normalised into a single correct data source

- An accurate geological model was built as well as visualisation of past excavation sites

- All this combined information provided an accurate geological and quality model, accurate resource estimates and mine plan

Social Media

See our blogs

Studio OP V3.0 Release

June 10, 2024

New product alert! – CCLAS EL Mobile App v1.0.0

April 29, 2024

DATAMINE EXPANDS ASSET MANAGEMENT SOLUTIONS

April 15, 2024

-

Peabody & Datamine Consulting

Peabody Identified Gaps Within Their Operations And Improved Their Overall Technical Capacity With Datamine's Consultants

-

Rio Tinto & CCLAS

Automated Processes And Tracked Data Flows Enabled Rio Tinto To Improve Operational Outcomes - Saving Up To 1 Month Per Year In Manual Work, Significantly Minimising Data Errors And Increasing Processing Capacity

-

Advaita Group DMCC & MineMarket CTRM

Better Informed Decision Making And Data Analysis, And Significant Time Savings On EOM Reporting Using MineMarket